Slip Resistance Explained

Slip-Resistance Explained

Slips, trips and falls case a large amount of hospitalisations in workplaces, public environments and at home. The risks of slips can be reduced by selecting the right floor materials or upgrading flooring with non-slip coatings. The New Zealand Building Code and the New Zealand Standard for Slip Resistance (NZ4586 and NZ4663) specify which slip-ratings are required and which tests can be conducted:

• Wet pendulum (P rating test)

• Oil wet inclining platform (R rating test)

The Australian Hand Book HB 197, An Introductory Guide to the Slip Resistance of Pedestrian Surface Materials, mentions both ramp or pendulum slip testing classifications. However, it does not prefer any standard. However, it is important to know the difference between the two methods. For example, pendulum slip testing can be done on-site and in a laboratory. Ramp tests can only be performed in a lab. So R-rating cannot be verified once a flooring material is installed.

Which Test To Use?

In general, the wet pendulum test method (P rating) should be used in all situation where surfaces can get wet and are accessed barefoot and/or with shoes. The ramp slip resistance method (R rating) is only useful for areas that get oily such as commercial kitchens and industrial workshops.

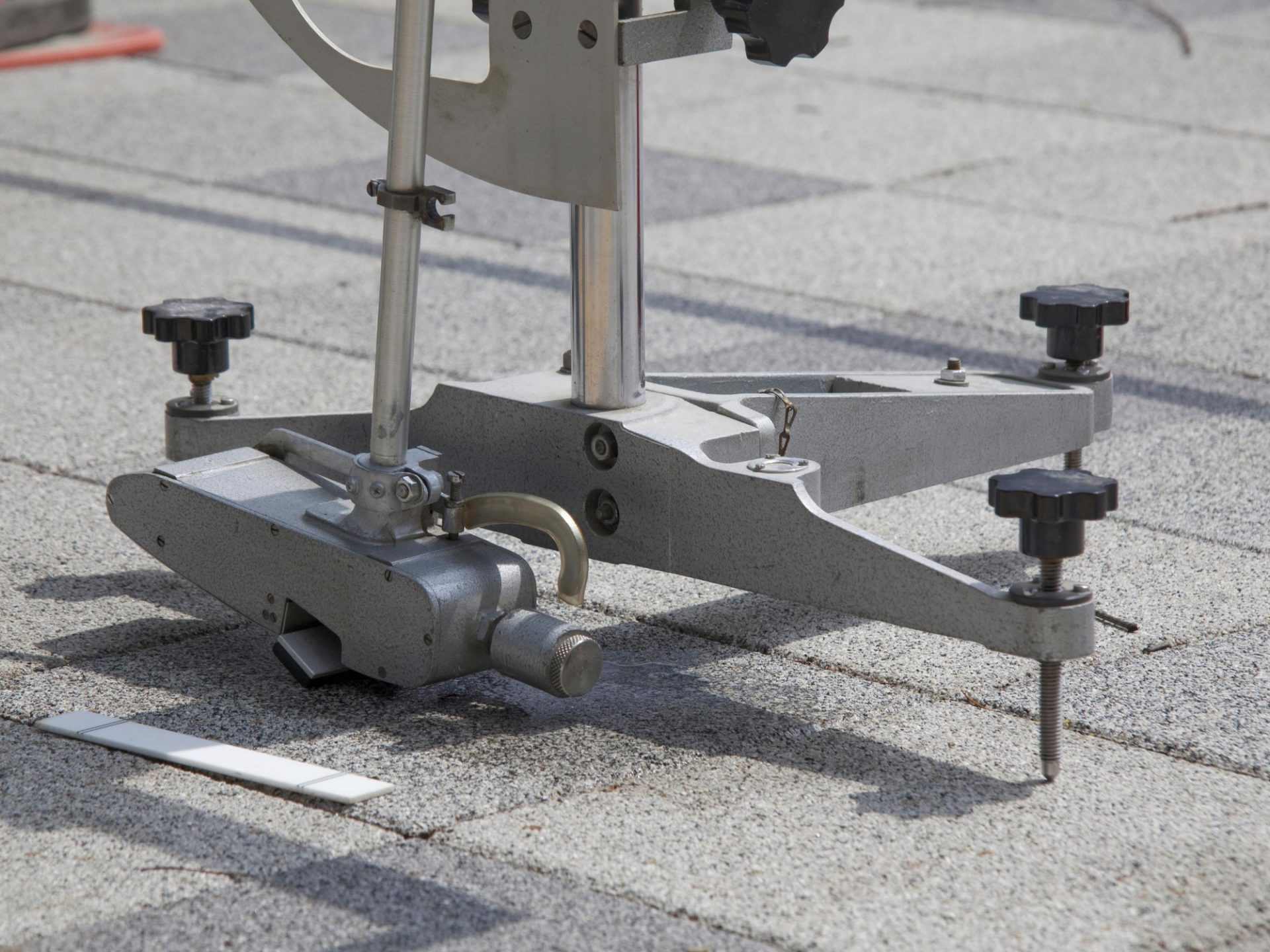

Pendulum Test: NZ4586 and NZ4663

The New Zealand Standard for slip resistance includes a wet pendulum slip test for both new and existing surfaces. The standards are NZ4586, Slip resistance classification of new pedestrian surface materials. Furthermore, NZ4663 concerns Slip resistance measurement of existing pedestrian surfaces.

For both tests, two different type of sliders are used. Firstly, slider 96 is used for pedestrian surfaces. Secondly, slider 55 is used to test the slip resistance for barefoot surfaces (bathrooms, pools, etc.). Therefore, Slider 55 is softer and resembles the skin of our feet, whereas Slider 96 is rubbery and resembles a shoe sole. To conduct a valid test, five measurements are taken and the combined average of these tests provide a Slip Resistance Value (SRV), which in return provides a wet pendulum class.

As can be seen below, P0 represents a very low rating, whereas P5 provides the highest slip-rating. However, this does not mean that a P5 slip-rating should always be preferred. Many P5 solutions are very rough and not suitable for a bathroom, pool area etc. Moreover, the New Zealand Standard has specified specific slip ratings for specific areas.

| Wet Pendulum Class | SRV Slider 55 | SRV Slider 96 | Risk of Slips |

|---|---|---|---|

| P0 | < 12 | – | |

| P1 | < 20 | 12 → 24 | Very High |

| P2 | 20 → 34 | 25 → 34 | High |

| P3 | 35 → 39 | 35 → 44 | Moderate |

| P4 | 40 → 44 | 45 → 54 | Low |

| P5 | > 44 | > 54 | Very Low |

Wet barefoot inclining platform slip-resistance (Appendix C of NZ4586)

In this test, a sample is mounted on an inclining platform surface. Next, a person in a safety harness will walk up and down on the surface while water is sprayed on the surface. The angle of the inclining platform is raised until the test person feels that walking will result in slipping. From several tests, the mean angle of inclination determines the slip-resistance rating.

Results are categorised into three classes:

| Wet Inclining Platform Test | Angle | Slipping Risk |

|---|---|---|

| A | ≥12° | High |

| B | ≥18° | Medium |

| C | ≥ 24° | Low |

Oil wet inclining platform slip-resistance (Appendix D of NZ4586)

This test is designed for industrial surfaces, but often used to indicate the slip-rating of tiles. The test uses the same equipment as described above, however motor oil replaces water as the wetting agent and safety boots are worn on the feet.

| Oil Inclining Platform Test | Angle |

|---|---|

| R9 | ≥6° & ≤ 10° |

| R10 | ≥10° & ≤ 19° |

| R11 | ≥19° & ≤ 27° |

| R12 | ≥27° & ≤ 35° |

| R13 | ≥35°. |

R-Ratings are often used by tile manufacturers to indicate the slip rating of their tiles. However, this is often only an indication. Rarely are the tiles tested by an independent institution for their slip-rating. This is one of the main reasons why tiles fail independent slip tests after installation. This problem occurs especially when the surface is tested in wet or oily conditions.

Because the platform or ramp tests is conducted by a person and not by a “machine” like the wet-pendulum test, it has been debated if is a good test to measure the slip-resistance of a surface.

Accelerated Wear Test

Recently, the accelerated wear test has gained importance. The test aims to show the probable long term slip resistance of a surface. The test subjects a floor sample through a number of cycles of wear. After each cycle, the slip resistance is tested with the wet pendulum slip resistance testing method.

This method is gaining more importance because many tiles and flooring materials show high wear. This means that some surfaces (such as tiles) have an initial good slip-rating. However, this rating rapidly wears down, sometimes within months or even after several cleaning cycles.

The Swiss GriP Non-Slip Coating is one of the few solutions that conducts accelerated wear testing. Our coatings have shown to outperform many tiles with outstanding wear resistance.

Swiss GriP Non-Slip

Looking to upgrade and existing floor or a new floor to the right slip-rating? Swiss GriP Non-Slip is New Zealand’s leading transparent and CSIRO-certified non-slip solution. Have a look at our durable solutions below.

Swiss GriP Certifications and Awards

Slip Resistance Requirements

The CSIRO/Standards Australia Handbook (HB198:2014) provides recommendations for what degree of slip-resistance is required for different uses, areas and environments.

Meeting or exceeding slip resistance standards

To completely reduce slips and falls, Swiss GriP gives you the possibility to meet or exceed the required slip-resistance standard without creating a rough of unappealing surface. Our coatings are CSIRO certified with P3, P4 , P5 and R11 and R12 Slip-Ratings.

Because Swiss GriP is independently certified by CSIRO in accordance to NZ4586, you will know upfront which slip rating your floor will achieve after Swiss GriP is installed. To get a precise result it is possible to have your new Swiss GriP surface tested in accordance to NZ4663. Moreover, our coatings have been frequently tested after installation.

Contact Us For A Free Consultation

Swiss GriP Non-Slip: Independently Certified

Unlike anti-slip treatments, Swiss GriP is certified by independent institutions like CSIRO Australia with the best possible slip-resistance ratings. This means our coatings not only eliminate the risk of slips and falls, they also provide protection against liability claims.

CSIRO Test Report (NZ4586): Swiss GriP NonSlip PRO Transparent: (Download – PDF)

CSIRO Test Report (NZ4586): Swiss GriP NonSlip Floor Coating: (Download – PDF)

Test Results

Wet pendulum test method (slider 55): SRV: 54. Slip Rating: P5

Wet pendulum test method (slider 96): SRV: 76. Slip Rating: P5

Swiss GriP Non-Slip: Backed by Science

No other non-slip solution has been tested and approved by independent experts and institutions like Swiss GriP. Our coatings score the best possible results in wet pendulum tests as well as ramp tests in Europe, Asia and North America.

| Country | Norm | Institution | Slip Class |

|---|---|---|---|

| United Kingdom | BS 7976 | Satra Technology | SRV: 0.50 (Best in Class) |

| Germany | DIN 51097 | TÜV Rheinland | Class C (Best in Class) |

| Germany | DIN 51130 | TÜV Rheinland | R10, R11 & R12 |

| Switzerland | BFU 9729:2007 | EMPA | GB2 & GB3 |

| USA | ASTM E 303/93 | Falco Bauer | SRV: 0.55 |

| South Korea | KS M ISO 11220:2014 | LG Hausys | SRV: 0.80 (Dry Conditions) SRV: 0.55 (Wet Conditions) |

Contact us for a free consultation

Any questions about slip-resistance requirements? Fill out the form below for a free consultation. We reply within 24 hours. You can also call us at (03) 7020 2041 for a direct consultation.